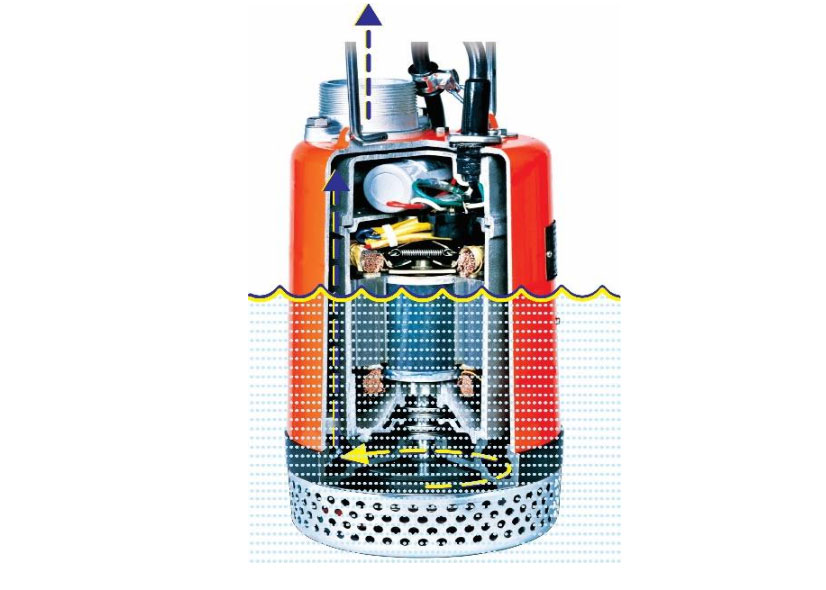

Submersible pumps require no priming since they are in the water source. This eliminates cavitation and the need for suction hose.

A hermetically sealed motor close-coupled to an impeller uses rotary (kinetic) energy to pressurize and discharge water from the pump to the surface via hose or pipe.

Performance is measured as either flow (gallons per minute) or pressure (head). Debris and solid handling capability varies by pump design.

There are two distinct types of pumps: (1) Centrifugal (often referred to as semi-trash) and (2) Centrifugal Trash.

Who uses submersible pumps?Underground and general contractors, emergency response, pool contractors, public works groups, municipalities, landscapers, plumbers, utility organizations, clean-up / restoration businesses, and DIY.

Where are submersible pumps needed?

Well casings, excavations, ponds, standing water, flooded rooftops and basements, swimming pools/spas, transformer vaults, and manholes.

What else may the customer need?

Operators may require control boxes, float switches, either NPT Thread or Cam & Groove quick disconnect hose, filter socks, couplers, PVC pipe, stability platforms, generators and tethering cable.

What type of fluid does a submersible pump handle?

Standard Centrifugal pumps handle water and small amounts of debris both in size and volume content. These pumps also can support a small percentage of selected chemicals laced in the water source. Trash pumps handle water that has higher amounts of debris both in size and volume content. These pumps also can support a small percentage of selected chemicals laced in the water source.

DID YOU KNOW? MQ submersibles can pump water temperatures up to 160°.

Learn more! Download the MQ submersible pump brochure or the MQ Pumping Handbook at multiquip.com