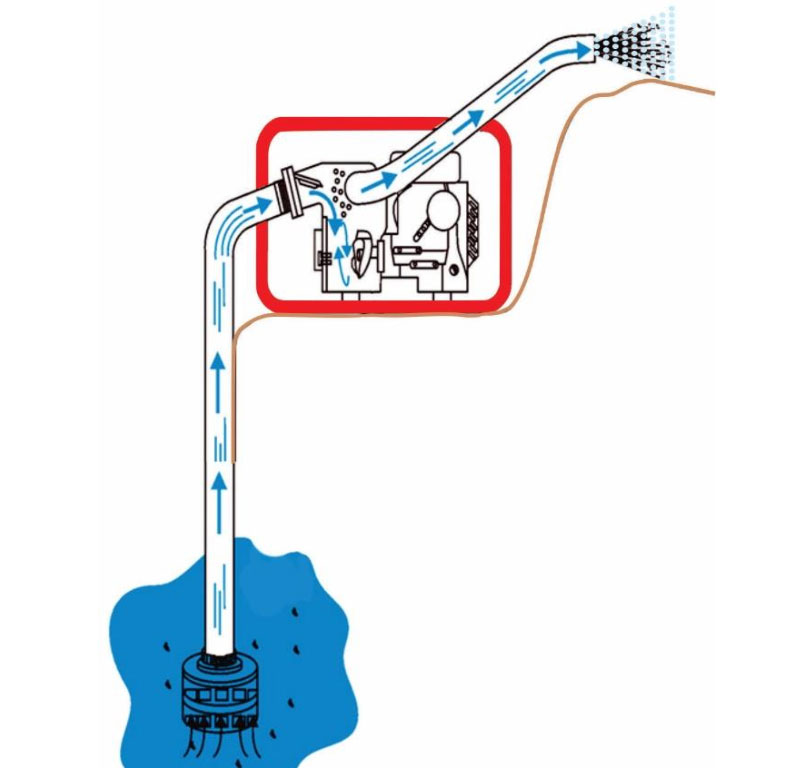

Centrifugal pumps use kinetic energy from a rotating impeller to move water. A rotating impeller churns a mixture of air and water inside a spiral casing (volute) that purges air from the pump. This action primes the pump by creating an area of low pressure within the housing. This in turn creates the “lift” necessary to move water through the suction line and into the housing where it is pressurized and discharged from the pump at considerable velocity.

Performance is measured as either flow (gallons per minute) or pressure (head). The head developed is approximately equal to the velocity energy at the periphery of the impeller.

Standard centrifugal pumps provide very good flow performance for primarily clear water applications. Can handle 10% solids by gallon weight and debris approximately ¼ the size of the suction-inlet.

Trash Pumps provide exceptional heavy fluid flow performance. They can handle approximately 25% solids by water weight, and move debris ½ the size of the suction inlet. Trailer mounts available for selected models.

High Pressure Pumps

are designed to provide very high head, high pressure jetting performance. They require clean water sources, and cannot pump debris laden fluids.

Who uses centrifugal pumps?

General contractors; farmers, residential and commercial operators, municipalities, government agencies, first response organizations, commercial boat operators, firefighting organizations, pool and spa service companies, public works departments.

What types of engine powered kinetic pumps are there?

Standard centrifugal, Trash and High Pressure.

Where are dewatering pumps needed?

Site preparation, utility operations, municipality and public works response, agricultural irrigation settings, protective fire-fighting options, residential standing water removal, emergency flooding response, sewer dewatering operations, water relocations, dust control and water jetting.

What else may the customer need?

Operators may require either NPT Thread or Cam & Groove Q/D disconnect suction hose, couplers, PVC pipe, gate valves, NPT Thread or Cam & Groove Q/D disconnect discharge hose, couplers and wheel kits.

DID YOU KNOW? Multiquip offers more portable high pressure pump models than any other manufacturer.

Learn more! Download MQ Dewatering Trash Pumps brochure or the MQ Pumping Handbook at multiquip.com