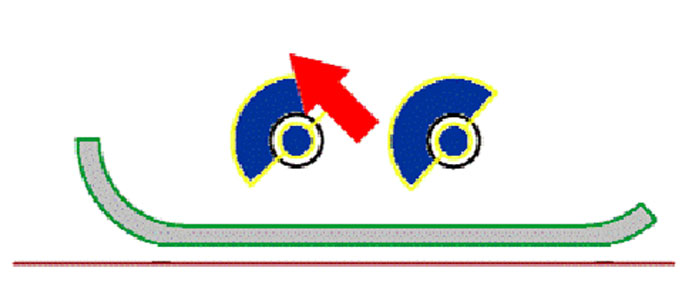

Reversible plate compactors use a hydraulic drive to adjust twin rotating eccentric shaft mounted on the baseplate. The positioning of the weights allows forward, reverse or spot compaction. The result is LOW amplitude, HIGH frequency VIBRATION that consolidates the material, removes air pockets and increases load bearing ability.

Who uses plate compactors?

Asphalt, underground, concrete and general contractors; landscapers, utilities

What soil types are best for plates?

Ideal for compacting granular material and in some cases asphalt

Where are plates needed?

Site preparation, decorative asphalt, confined areas, utility construction, residential, plumbing and landscaping

What else may the customer need?

Users may require transit levels, shovels, safety equipment, skid steers, mini-excavators and water trailers

DID YOU KNOW? Selected MQ reversible plates include bolt on extensions that allow you to change the plates working width.

Learn more! Download Reversible Plate brochure or the MQ Soil Compaction Handbook at multiquip.com